High-Resolution Emulsion Analyzer HEA100

|

The High-Resolution Emulsion

Analyzer HEA100 is designed to test the stability of water-based

agrochemical

emulsions which are widely used in pest control. Easily

surpassing current techniques, the turbidity fluctuation

analysis technique can quickly and precisely characterise

emulsions to bring significant benefits to testing in

the development of new formulations and the quality of

manufactured emulsifiable concentrate products.

- Rapid, objective measurements.

- Extremely simple to operate.

- Highly sensitive to droplet size change.

- Convenient flow-through system.

- Compact and lightweight.

The HEA100 has been developed in collaboration with Zeneca

Agrochemicals and has successfully completed

UK trials involving major manufacturers. |

Testing Emulsions

Good stable emulsions are characterised by very small droplets

and by a fairly narrow distribution of droplet sizes, although

the actual values will

vary between different formulations. These properties should

not change over periods of many hours or even longer.

The HEA100 is designed to detect the size of droplets in oil-water

emulsions using a simple procedure. A prepared emulsion sample

is siphoned through

a capillary sample tube mounted in a flow cell on the front

of the instrument. After 1-2 minutes a reading related to the

stability (R) is displayed:

further tests can be conducted after flushing the sample tube

clean.

Results achieved show good correlation with the traditional

CIPAC test, but with significantly greater sensitivity and taking

only a few minutes.

An optional validation unit is available to confirm the test

performance of the instrument and for compliance with ISO9000

quality assurance procedures.

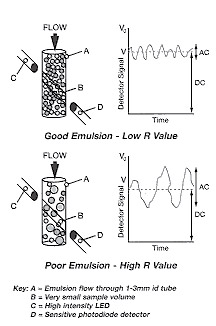

Operating

Principle

The HEA100 uses an optical system developed at University

College London that responds to the changes

in the size of droplets flowing through the measurement

cell, as indicated in the diagram.

A laser light beam illuminates the flowing emulsion

and the transmitted light is monitored by a sensitive

detector,

which produces a signal comprising two components:

- An average (DC) value related to the turbidity of

the emulsion.

- A smaller, fluctuating (AC) component arising from

random variations in the number and size of the droplets

--in the laser beam.

In unstable emulsions, droplets become larger in size

and smaller in number, which leads to an increase

in the AC component. A measure of the emulsion stability

is derived from the ratio of the AC and

DC components, which is displayed as a reading R. The

higher this reading, the larger the droplets and

the lower the emulsion stability. Conversely, a small

R value indicates a stable emulsion.

|

|

Applications

The stability of emulsions must be tested to ensure their efficient

use and proper application. A rapid assessment of the emulsion

stability using

The HEA100 will help to prevent breakdown of emulsions and the

formation of oils and creams.

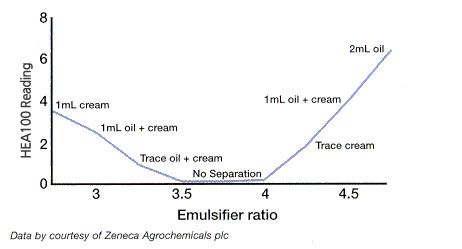

In

developing a formulation

A plot of results using different emulsifier ratios

enable the optimum formulation to be selected.

For routine quality monitoring

Frequent measurements quickly identify potential stability

problems and corrective action can be taken during manufacture.

Technical Data

The HEA100 is supplied with 6 capillary sample tubes, 2mm

silicone tubing, Hoffman clip to adjust flow rate, 250ml beaker

tubing clamp assembly

and a suitable power lead.

- Light source : Laser, 670nm, output 0.95mW.

- Sample flow rate : 10ml/min ±10%.

- Measurement accuracy : ±5%.

- Display: Readings (R) and DC volts.

- Overload indicators: Large particles and turbidity.

- Power supply: 110/120V or 220/240V AC 50/60Hz.

- Size: 320mm (w) x 200mm (d) x 165mm (h).

- Weight: 4.0kg.

Ordering Information

|

Order Code |

Description |

| HEA001A |

High-Resolution Emulsion Analyzer HEA100

& validation unit |

| HEA002A |

High-Resolution Emulsion Analyzer HEA100 |

| HEA003A |

Validation unit for HEA100 |

| HEA170A |

Glass sample tube |

| HEA172A |

Silicone tubing (2 mm bore, 1 mm wall) |

|